What You See is What You Get? Maybe Not

A chicken breast with five types of foreign materials in the photo: pieces of wood (tan), a polyethylene plastic box (white), a nitrile rubber conveyor belt (green), a polyethylene conveyor belt (white), and a polyurethane conveyor belt (blue). (Photo courtesy of Seung-Chul Yoon)

Hyperspectral Imagery May Detect Foreign Matter on Meat

There may be more than just seasoning on that meat you’ve been eating; there may also be small pieces of metal, plastic, glass, or rubber.

According to USDA, foreign material contamination is one of the primary reasons for food recalls and public health alerts (34 of the 124 cases in 2019), a trend that has been increasing since 2012. Scientists with the Agricultural Research Service (ARS) are investigating the use of a technology called hyperspectral imagery to detect these materials in poultry before they enter the consumer supply chain. The technology involves taking a series of digital images over a range of different light wavelengths.

“Foreign materials such as metal, plastic, and rubber pieces are routinely found in poultry meat products,” said Seung-Chul Yoon, electronic engineer at the ARS National Poultry Research Center in Athens, GA. “The main illnesses caused by foreign materials in food are physical injuries and choking. Injuries might include a broken tooth or a cut in the mouth or digestive tract, which can be related to hard or sharp foreign materials such as metal and glass,” he said.

Foreign material usually gets onto chicken products through processing plants, Yoon said. Most of the material comes from the wear and tear of processing equipment and machinery, wood pallets, and the personal protective equipment of plant employees.

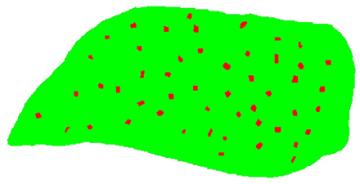

Hyperspectral imagery shows the foreign materials on the same chicken breast. (Photo courtesy of Seung-Chul Yoon)

In addition to developing hyperspectral imaging technologies to detect and identify foreign materials during meat processing, Yoon and his colleagues are developing artificial intelligence (AI) technology for smart sensing and robotic removal of the materials they find. While the project is working specifically with the poultry industry, the technology and processes could be applied to other food products too.

Hyperspectral images can be processed and analyzed to reveal hidden features that are not otherwise detectable. In this project, Yoon adopted hyperspectral imaging modalities in two wavelength ranges to develop detection and data fusion methods.

The fusion method detects foreign materials on the surface of fresh raw chicken breast fillets to accuracy rates of 100% for 5 mm x 5 mm pieces of polymer, wood, and metal. Accuracy rates at 2 mm x 2 mm sizes were 95%, 95%, and 81% for the same materials, respectively.

“It’s important to develop state-of-the-art technologies in hyperspectral imaging and AI that make a positive impact on food safety and are commercially viable,” Yoon said. “Once the technique and system are fully developed, they can be generalized to solve similar problems in other industries.” – By Scott Elliott, ARS Office of Communications.

You May Also Like